It’s time for me to get started on the cloth for the vest which means sharpening my virtual pencil by getting out the spreadsheet and weaving software to make sure I put on a big enough warp, have enough heddles and that I’ll have a shot at getting sufficient cloth to make the garment.

Rather than using the pattern I drafted, I decided to go with a store-bought version because it has full instructions for doing a fully-lined, turned vest. I’m pretty confident in my ability to make small changes (shoulder slope, waist location/length, etc.) and, since there aren’t any sleeves, the armholes should be able to stay as drafted. However, since it’s a commercial pattern, there’s this pesky problem with fabric size and cutting layouts. That means doing some math.

Step 1: Open up the pattern and pull out the instructions/cutting diagram. Here’s page 1 of the pattern.

It’s number 6075 from New Look/Simplicity – and their “Project Runway” series. Before you start giggling, it’s pretty much the only one I could lay hands on that didn’t look like I’d just washed up on the shores of a Caribbean island. And, it’s pretty nice. The instructions are clear and I’ve liked their patterns in the past. Plus, at $4, the price was right. :-)

Next up, a close-in of the cutting diagram. Please take particular note of the two grey pieces on the far left of the upper drawing.

This is where it gets interesting. The simplest (and safest) estimate is to look at the 44″/45″ wide fabric estimate for my size and double it since I’d be aiming for cloth of ~22″ wide. The pattern calls for 1 1/2 yards of 45″ wide fabric, without nap – so I should be aiming for three (3) yards of 22″ wide fabric. Simple, right? Sure. Except for those grey pieces.

In the view I want to make (View A, with the collar – because I think the collar looks better), I need to cut two looooooong collar pieces. Instructions call for them to be cut on the fold, cross-grain, so that they’re effectively a single piece wrapping around. From the get-go, I can’t do this. I’m not interested in weaving 45″ wide (finished) fabric as that’d mean double-weave at a minimum plus the loom waste would be silly. So, that leaves me to cutting and seaming. In principle, it should be ok, but I don’t know enough about how these things work to know what it’ll do to the way the collar behaves. The seam would be at the center line of the back neck and that also implies a build-up of layers. I’m also a tiny bit concerned about making sure that I have a wide enough piece of cloth so that I can cut the four collar pieces, now with seam-allowance at the fold, and join them to make the two large pieces. I went ahead and measured the pieces for my size and they clock-in at just over 20″, so in theory, they should be fine. Emphasis on “should”.

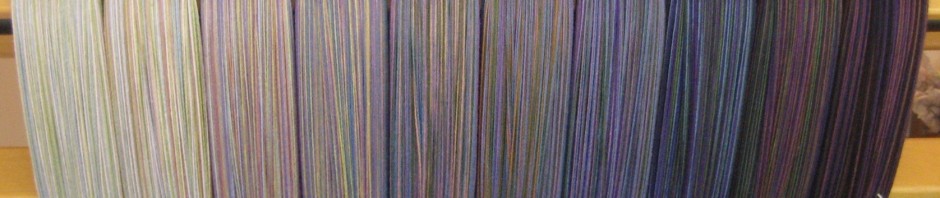

Next is the cloth itself. From my sampling, I get about 15% shrinkage in length and 17% in width. If I get out the calculator, I need to weave the full-width of the BW, 26″, to get a 22″ (almost!) overall piece. And, I need 3.5 yards woven to get three yards finished. The medallion is a 32-end pattern, so I get 29 medallions plus eight ends left over, and I’d thread those for plain weave selvedge – four on each side. I’m pretty sure I can turn the draft so that I’m weaving with a single shuttle, which will make it go much faster, but that means warp rather than weft floats – and I’m a little concerned about tension issues over more than three yards of weaving. Intuition says that it should be fine, since they’re evenly distributed. Regardless, turning the draft makes all kinds of things go more quickly so I should just do it. Then again, given the turn, I may get a reverse in the shrinkage – more in the length (floats) than in the width, which would help me with the collar pieces but hurt me in fabric length. If I end up being short, I can always delete the collar.

If you managed to get through all that, congratulations! In a nutshell, here’s what I’m wondering:

- Other than possible difference in shrinkage rate, can you think of a good reason why I shouldn’t turn the draft? I’m highly motivated to do this.

- What, if any, are the ramifications of having a seam in the middle of the collar? Remember, this is a fully-lined/turned piece, so it’s the build-up of seams that I’m most concerned about. But what else?

- Also, if I turn the draft, my grain goes in the opposite direction. It also means vertical rather than horizontal squares. Should I go with that? Can I ignore grain and turn my fabric?

What else should I be thinking about? (or should I just get my ass in gear?)