I’m finally plowing along on getting my vest fabric going (yes, still behind) but I’m going to say that the gamp fabric counted as a sample, so I’m half way there. Maybe it’s a bit of cheating, but given how much I liked the twill once it was finished, I’m sure it’ll make it’s way into a garment at some point. Even Chris approved of it. “This’d be a nice jacket, I think.” On to the second fabric. Weaving with finer and finer yarns seems to be my current path and this was a chance to start digging into the 2/26 mill ends I picked up from Webs last year. I’ve got four colors – navy, light pink, and two tans – a dark and a light. There’s definitely enough there to make a sizeable piece of fabric so putting on a sample warp isn’t a dead end. Also, if you recall, I’d been reading an old Shuttle Craft that had a series of articles on M’s and O’s done with a new “Drapery Cotton”. I’m inferring that this is equivalent to the 8/2 unmercerized that I use for dishtowels, but that wasn’t going to be anywhere near fine enough for what I wanted. Enter the 2/26. After doing research, both from the article and from poring over other projects, I decided to just sett the fabric for a plain weave as a starting point, and then sett a subsequent piece a little closer. Also, the M’s and O’s are a four-shaft pattern (though Harriet Tidball has an expanded one on six or more shafts to yield a true tabby) so it’d be uncomplicated to start. Famous last words. Anyway, on to details:

- Draft Pattern – standard 4-shaft M’s and O’s, 32 end repeat

- Yarn – 2/26 wool, tans as the warp, will use all four for weft

- Sett – 32 epi, 4 ends per dent in an 8 dent reed

- Warp – 10.5″ wide in the reed (’cause I can’t count) and 3 yards long

- Beat – 32 ppi for balanced plain weave

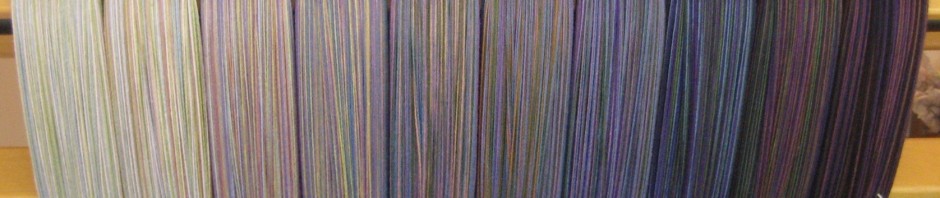

I also decided to use Tidball’s “false tabby” on the selvedges (harnesses 1 and 4, threaded alternately). I wound the warp, beamed on, threaded, sleyed and wove a lovely header row. Oddly enough, it was plain weave all the way across. And, on the first pattern shed, it hit me. I’d only threaded the “M” blocks (1/2 and 3/4). All the way across. And, while interesting, it’ll not give me anything even close to what I was after. So, I untied, pulled it out of the reed and re-threaded half the ends to give me “O” blocks. The good news is that each repeat of 16 ends used four heddles on each shaft – regardless of which block I was threading. I certainly could have been worse. And hey – it looks great!

|

I’m alternating the dark tan with the navy for this first section, then I’ll start rotating in the light tan and the pink so see which I like the most. So far, the tabby sections are beating to square and I’m already seeing the distortion of the float blocks.

|

In the above picture, you can see the transition from the dark tan (on the right) to the light tan (on the left). The reed marks look a lot stronger in this picture than they do on the loom and I’m hopeful that they’ll wash out when I finish the fabric. Then, once I finish the block and resley for a finer sett, I’ll rethread for a twill – just to get a little experience with that threading and this yarn. Plus, that can count as another sample for a future piece. Another reason why I went with the three yard warp. Feels like I should get plenty out of this exercise. Finally, Lynn, you were asking about Complex Weavers. I had been thinking about joining that guild – again, as a way to continue to have accountability and also to try and build a sample book. I’ve signed up for the “Beyond Plain Weave Garments” study group, which includes a once or twice per year sample exchange. The goal is fabric for garments (perfect!) and “Beyond Plain Weave” is a very loose definition. It can be fabric structure, yarns, whatever. And, as part of the exchange, I’ll get a piece of everyone’s fabric along with details on yarns, structure, and any notes they have on how the fabric behaved as part of being sewn. I only get samples when I contribute, and I don’t get kicked out if I don’t contribute. We’ll be doing an exchange in September – plenty of time for me to get a vest (or three!) done. And the samples are small – only 3″ x 3″, and can even come from waste material that otherwise falls on the cutting room floor. My kind of bunch. That’s my update so far. I’ll trot all the goals for the quarter out in a week or so – and start thinking about Spring!