So the three of us are here because we want cloth. Not just a “woven thing”, but a thing with a purpose. And, even more specifically, my intended purpose is cloth suitable for clothing. Granted, that’s a pretty broad definition – since clothing is a ridiculously broad category. However, there are some basic requirements that clothing must meet in order for me to consider it “good”.

First of all, the fabric must be suitable to the garment. A coat for winter should not be prone to fraying and also be (somewhat) weatherproof. Insulating is a good idea, too. A summer skirt, on the other hand, should be lightweight, breatheable, and preferably “flippy” for when I’m scurrying across the street or trying desperately to blend in on the Stanford campus.

Second, the cloth needs to be able to be cut and sewn/tailored. That means that it won’t pull apart at the seams or immediately begin fraying at a cut edge. Granted, there are things that I, as the seamstress, can do to help prevent these things, but I also think that I, as the weaver, can engineer this into the cloth itself.

Finally, it should please my senses. That means color, texture, and drape. It should *feel* good when I put my hands on it. Looking at it should make me want to look closer as well as look from a distance. It should move and flow in such a way that it gives me the sense that it was made with thought and care.

And so, with all that in mind, and with some help and support from Sara, this is my first attempt at cloth. I do this knowing full well that it won’t meet all of the above criteria, but that same Sara has reminded me that the act of doing is what will lead to better and more predictable outcomes. And, if the act isn’t finished, then the opportunity to learn is reduced.

First yardage, here we come:

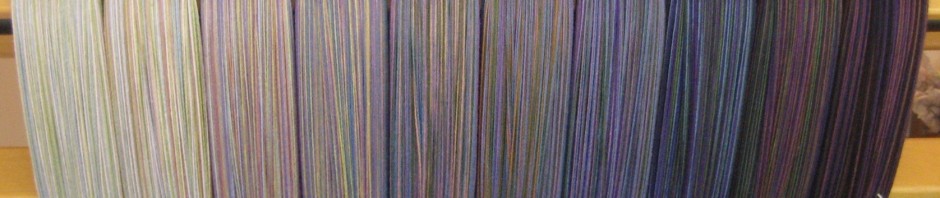

8/2 Unmercerized cotton from Webs, sett at 24 epi. The warp overall is, hmmm, just about 19.5″ wide. The blue light blue threads off to the right hand side of the warp separate the body fabric from the collar band. I don’t think the stripes will hit where I want them exactly, but we’ll see.

First yard is woven off (see the teeny pin near the top of the left-hand purple stripe?). Weft is 10/2 Mercerized cotton, also from Webs. I’m not worrying about my picks per inch, rather, I’m beating with a “medium” amount of force. Just enough to place the thread, but not really banging it in there. The green of the weft has softened the brown stripe too much, I think, but I’m just crazy about what it’s doing to the blue and the purple. Absolutely excellent.

And finally, a close-up of the three color bands from the collar section. Each of the stripes is made up of either two or three colors that were held together when warping but threaded somewhat randomly. Note how the brown looks almost solid whereas the other two are distinctly striped.

So, Lynn and Sarah – what are you guys up to?