A big thing that weaving has taught me is not being able to simply give up on something once it gets difficult or after I’ve made a mistake. Now, I’ve never been one to do anything in a small way and the same holds true for my mishaps. That said, here’s what’s been making me crazy of late.

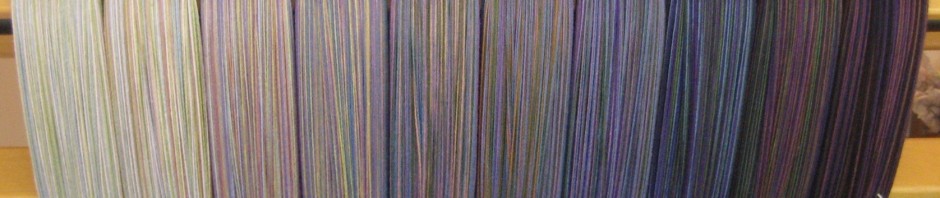

Back in early October (I’m nearly ashamed to say that) I put on a gradient warp. I sell a lot of dishtowels, both around the holidays and at our annual Art Fair and this was an attempt to get ahead of the game so that things don’t get so hectic in mid-August. The gradients are fun to plan/wind and the resulting towels are really quite lovely. So, great! A long warp and hopefully 15 towels to go into the bin post-haste.

Fast forward to starting to thread and me counting out the ends in the first section of the warp. Rather than hitting the end of the section after the expected number of threads, I was only halfway through. I sat there, slightly puzzled, and then it dawned on me – I’d wound twice as many ends per section. (Have I mentioned that AVL Warping Wheels are fun?) I quickly grabbed another section and sure enough – same problem. Oh, crap. That whole beam is wound incorrectly. And that’s not a 15 yard warp, it’s effectively a 30 yard warp. Too much yarn to simply cut off and bin so I had to do something. I started thinking about doubleweave placemats (but they’d be too wide) or maybe a few lengths of cloth (but I wouldn’t want that gradient and I’d not done anything to manage the fold) or even maybe something purely artistic (but 15 YARDS WORTH?). I knew doubleweave would be in there somewhere but it was time to head off to SOAR and I could just let it rattle around in the back of my brain for a couple weeks.

Now, shortly after SOAR I went off to Boulder for a weaving class with Sharon Alderman and that gave me the kick in the butt I needed – in a variety of ways. Resolved: doubleweave, separate lengths of cloth that could be cut apart as per usual. However – this is boring. Really boring. And slow because two shuttles. After three yards of this I was really starting to get antsy. Cue Sharon’s little voice in my head and my trusty copy of Fiberworks.

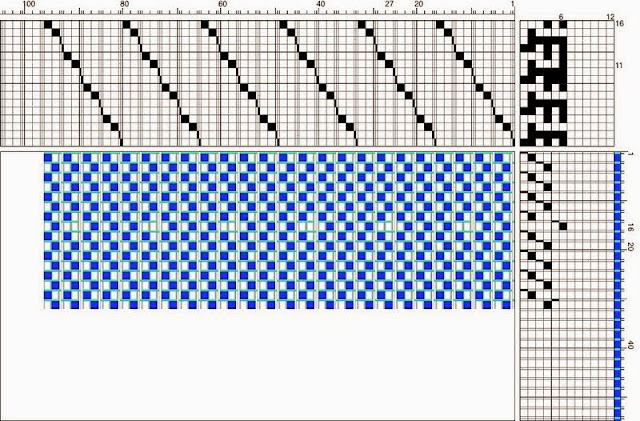

When I did my first shirt, I used Bronson to break up the long, vertical stripes. The gradient warp had that same vertical characteristic so I decided to see if I could manage a spot Bronson on a straight-twill threading. Oh, and I had to do it in doubleweave as well. One day of messing about, adjusting and fiddling yielded this:

The thickness of the warp and weft threads are adjusted so that I could visually check my work, but suffice to say, it worked! At least on the computer. Time to try it on the AVL:

Perfect. Love it. All those little skips are just what I needed to make it that tiniest bit more interesting. Granted, it’s a bit more challenging to address issues when I get a missed lift, but so far so good.

Speaking of which, I need to get back to it. There’s been no time this week because of a deadline and emergency tech-editing job but this is just what I need today. Rhythmic, lovely weaving. And yeah, I’ll let you know when they’re hemmed and ready to go to new homes.