Yeah, so it’s been a while since either of us posted here, but that doesn’t mean I haven’t been weaving. Oodles of stuff have come off the AVL and, with a request to weave a set of Summer and Winter towels, I decided it was time to dust off Gilly and weave on her for a while. I wanted to get my head around the structure and having to pay attention to the treadling order, and being able to make changes as I went are two things that aren’t as easily done on the AVL. So, off I went!

First step was to see if I could use the warping wheel to beam on a sectional warp. The height of the beam on the Gilmore is much lower than the one on the AVL, so I needed to decide how to deal with the differential between the beam on the loom and the comb on the wheel. It’s possible to change the height of the wheel, so I lowered it as much as possible (and now I would have to wind while seated) but there was still a good 12″ difference between the comb and the beam. With a little encouragement from a friend, I gave it a go. Worked a charm.

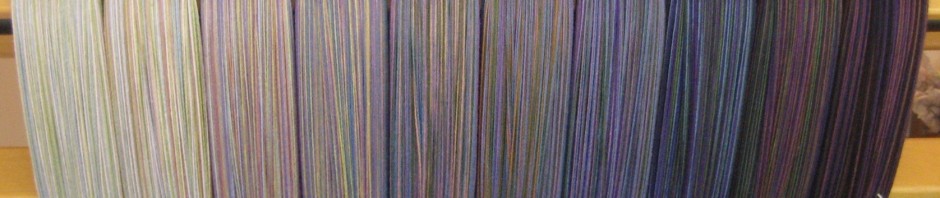

You can see that I’ve also angled the comb so that the width of the section matched the width on the beam. Once things were lined up, I wound on in no time. Mischief managed – and I’m another step closer to putting in an order for my own wheel. By the way – this also meant that I needed to make sure that I planned out my winding order so that the colors would change where necessary rather than just at sections. And, I even managed to pay attention to how the section gets built versus how it winds on so, amazingly, there were no mishaps in getting the warp on the loom.

I proceeded on to threading, sleying and checking for threading/sleying errors and everything looked just fine. It was nice to be able to thread so quickly; being able to flick the heddles into position and then out of the way is a luxury that the AVL doesn’t have. And, the little pieces of drafting tape that tell how many heddles are on each shaft continue to pay off. I was all set to go before the day was over.

Or at least I thought I was. There’s a bit of rehab that I’ve been putting off doing on this loom because I was pretty sure it was going to be a royal pain in the butt. Over time, the cushioning strips in the lamm guides, as well as on the underside of the jacks, go bad. Actually, they don’t just go bad, they do it by converting from foam to sticky goo that oozes down the sides of the loom and forms an unholy bond with the lamms. From a functionality standpoint, it means that the lamms and shafts actually stick when the treadles are depressed. I’d lived with it for a long time but it was even more annoying than previously after the ease of the AVL. So, when I sat down this morning to start weaving on the actual towels, I decided that I couldn’t deal with it any more.

Naturally, the best time to do serious maintenance on a loom is when it’s just been dressed and is ready to start weaving, right? Of course! So I dug out the instruction sheet and the four new pieces of foam that I’d gotten from Gilmore last year and had a good look.

See? Horrible. It’s been in need of doing for quite some time.

First step was to remove the two screws that hold in the lamm guides. See them there? One on the top, one on the bottom. Those, dear friends, are flat-head screws. The instruction sheet makes lots of noise about possibly not being able to get them out and warning against breaking them off in the process. I got Chris to come out and help because those screws were MURDER to try and remove and we got three out of four. The bottom one in the picture just wouldn’t budge. And, after we managed to cam out the slot, Chris resorted to getting out the Dremel tool and cutting a new slot. Eventually, that screw came out and we were able to get both of the guides out for cleaning.

I had to use an X-Acto knife to scrape off the worst of the perished cushioning; to give you an idea, here’s what the jack cushions looked like when they came off the loom:

and after scraping off the worst of the goop:

then, liberal applications of Goo-Gone, time, elbow grease and Murphy’s Oil soap, it was time to put on a new piece of foam:

and it’s ready to go back onto the loom.

I also had to crawl around underneath the loom because the lamms themselves needed cleaning. All in all, it was about 3 hours of work to get everything disassembled, cleaned and then reassembled. And, I must admit, it’s much more pleasurable to weave on it. The shafts raise and lower when they’re supposed to and even give a happy bounce when they drop. Massive improvement.

And, not surprisingly, it’s much less physically taxing to weave on the Gilmore. Mentally, OTOH, it’s a bit more challenging. But that’s all good, right? Because then I won’t think about the marathon I’m not running.

Now, back to the studio. I’ve got towels to weave.

Oh, you have my sympathies on those foam pads! I suppose this means I should replace the pads on my Norwood sooner rather than later, right?

And I think I understand the issue of different heights with the warping wheel, but I suspect seeing it in person, one of these years, would help my comprehension.

Let’s talk at SOAR about where we’re going with this blog. I certainly having been posting much either, although I have been weaving.