I think this project is the perfect example of why it’s important to actually weave something and not just read about it. It also continues to reinforce that sampling is good. I’d been muddling over how to play with color and texture in overshot and, in searching for some interesting references, found my way to Bonnie Inouye’s article in the now-defunct WeaveZine on Networked Twill. I read it. I read it again. I got out my laptop and fired up Fiberworks and played around. Regardless, I just couldn’t wrap my head around it so that left me no choice but to wind a warp and fire up the loom. Project Notes:

- Warp: 8/2 BFL from Ashland Bay (this is very loosely plied – I’d prefer a higher twist and may well run it through the wheel first next time)

- Weft: 8/2 Mill Ends from WEBS

- Sett: 20epi – 2 ends per dent in a 10 dent reed

Woven off at 20 ppi for as balanced a fabric as possible. I hemstitched at the beginning and after weaving off 75″, left some room for fringe and then wove off a bit more as a sample to keep. I gave the finished scarf a bath and also gave it a vigorous rubbing. I may well run it through the wash next load to see if the whole thing will full even more. I’d like it to be just a hint softer. The big learning here was how to manipulate the treadling to get curves – both slow, sweeping ones as well as sharp, zig-zaggy ones. It’s all about how slowly or quickly I work my way across the treadles. The threading is based on a 4-shaft twill, so a “closed” repeat is four picks. If I stop short, then I work “left” two treadles from the last (e.g. – if I end on 5, then I start again on 2; end on 7 and start again on 4, etc.). Now, I can extend the repeat to five six or seven picks, that just changes where I start for the next segment. It took about 18 inches of weaving before I started to feel confident about where things would go – and then it became fun!

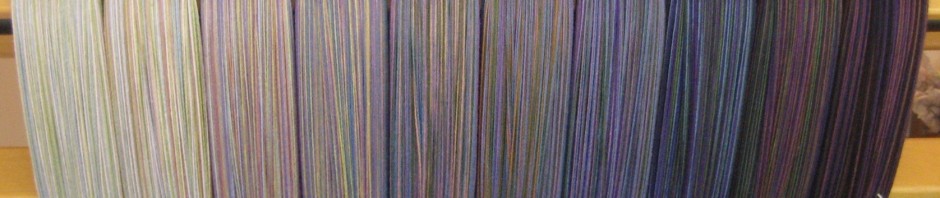

The other thing that happened was a noticeable rippling in the cloth. You can see that a bit in the picture above. The tie-up was a 3/1/1/3 so the cloth was “faced” and that, I think, is what helped give the added dimension. I was a bit worried about tension problems but as long as I kept moving those curves around, all was well. Bonnie’s original piece was done in silk and I did wonder how much of my tension stuff got absorbed by the wool. BFL is far from elastic, but it does forgive.

|

And, of course, I wove a bit of the sample at the end in my (continuing) favorite yarn. Yup, that’s the Dead Weaver Blue. I like the contrast so much more than the natural brown and, when I get to the real project, I’ll probably go for a darker weft. An inky black with hints of yellow and green (think asphalt) with white nepps. Should be fun. I’m going to fess up and say that I’m behind on my January list – I’ve not yet sewn the vest but I have been thinking about the fabric I plan to sample for next month. So, this weekend is for sewing and firming up sampling. I do think I’ll be able to get it all done. Just need to get off my (proverbial) duff. Post this weekend to recap on where I am against the list.

OK, my brain is not grasping this either, without weaving it, but yay for you, actually weaving this!

When you say there was a noticeable rippling in the cloth, do you mean it was moving up and down, out of the flat plane? WAs that true after the fabric was washed? After pressing?

yes – there is a definite corrugation to the cloth. And it’s still noticeable post finishing and pressing. The tie-up is for 3/1 twill over 8 shafts, so the light sections of cloth are warp-faced and the brown sections are weft-faced. Given that at any given point, there are both warp and weft-faced sections, that leads to a ripple.

I’m thinking about it like the dimension one gets with knit/purl in ribbing. It’s really pretty cool – and I’ve also been playing with different tie-ups on the software to get different effects as well. I don’t think Network will be a huge part of my weaving, but being able to draft curves *as I weave* is pretty cool. And fun!