In the “January” department, I had three things to do – two were vest related and the third was to weave a selvedge rug. Because I’m a contrary person, I started with the last one first. I got a big bag of selvedges from a “Dead Weaver’s Stash” on my last trip to Palm Springs and that was my excuse to give this kind of weaving a try. They’re the high end version of the selvedges that you can get from Pendleton. In my case, earth tones – browns, coppers and neutrals with the occasional splash of green. After poking around the web, I chose 8/4 carpet warp for the warp and threaded at 12 epi on the Gilmore. This was driven as much by which reed I had (either 8 or 12) as anything else. And, since the selvedges were so cheap, I didn’t have anything invested in this other than time. I wound a warp three yards long and 36″ wide. Nothing special on the selvedges – not even doubled. Threaded straight twill on four shafts, warped back to front as per usual.

I wove a header using tripled 8/16 cotton left over from the rep weave placemats for a few picks to ensure that my threading was correct, spread the warp and to give me some fabric to hem, if I chose to go that route. I wound the selvedges on a rag shuttle and started weaving.

This was, to say the least, a challenge. The selvedges make for a HUGE shuttle and the Gilmore doesn’t have the world’s largest shed. My compromise was to wind some of each selvedge length onto the shuttle and then to manually pull the balance of the weft piece through by hand. That cut down on the number of times I had to wind a shuttle and the weaving would have been super slow-going no matter what. The Gilmore can put very heavy tension on the warp, and I can beat heavily, but after about 18″ of weaving, I was knocking the pawl off of the back brake! This lead to a long pause while I had a look at the loom itself – and now I’ve a call to make to Stockton to discuss spare parts/rehab of this loom. Suffice to say the previous owner (at some point) made some mistakes with this loom and they need to be rectified. I don’t think anything is damaged, and if I’d never woven a rug I’d have been unlikely to run into trouble, but now I’ve got work to do. During the weaving, I felt pretty sure that I had sett this far too closely. The ends weren’t sticking up at all, but from what I’d read, this would happen as part of the finishing process so I forged ahead.

With the help of a clamp and a hefty dose of patience I finished the weaving with only three strips of selvedge left over. I wove a wider header on the back end and then tied a Damascus Fringe (ala Collingwood) on both ends. I really, REALLY liked the finish this provides and makes for a clean edge to the rug. Then the whole thing went into the washer with a hope that those little ends would come springing out and I’d have a lovely, shaggy rug. That, however, is not what emerged from the washer.

Rather, the rug is more like a super springy version of a rag rug. The selvedges fulled into squishy tubes and the ends are locked down. It’s wonderful to walk on – just not what I’d been aiming for. Also, the headers shrank up more than the rug, so they’re drawn in a bit, but I’m not bothered by that either. The rug has been holding down the fort in the kitchen for the time being but it’ll end up out in the studio shortly. It’ll also need some kind of non-skid mat underneath.

Project “Lessons Learned” and points for the next time around:

- Make sure the loom is fixed before I try this again.

- Sett at 6 epi. Either single or doubled, but wider sett for sure.

- Read Collingwood further and construct a better header row.

Amazingly, I do think I’ll make more – but that’ll wait until later in the year. Chris really likes the rug and it’s wonderful underfoot but there are other things to be done. Like my vest!

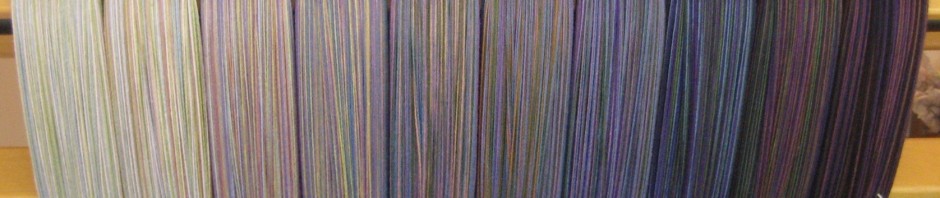

Oh, yes, that first close-up does look as though the sett was way too close. On the other hand, that’s likely to be a functional rug for a long time.

It’s kind of scary how long it takes to learn everything you need to know to weave a good thing, whatever that thing may be. You have to know how to tweak your loom – for that matter, you need to know if you’ve got the right loom for what you’re weaving. You need to understand what sett to use and how hard to beat and how best to handle the weft and how to finish the piece and on and on. It would probably take you five or six selvedge rugs to get all the kinks worked out – and how many selvedge rugs does one household and their beloveds need, anyway?